K1ND

Tube Clamp Restoration

Over the years we have done some remarkable

things to keep our Signal Ones running. Many parts are no longer

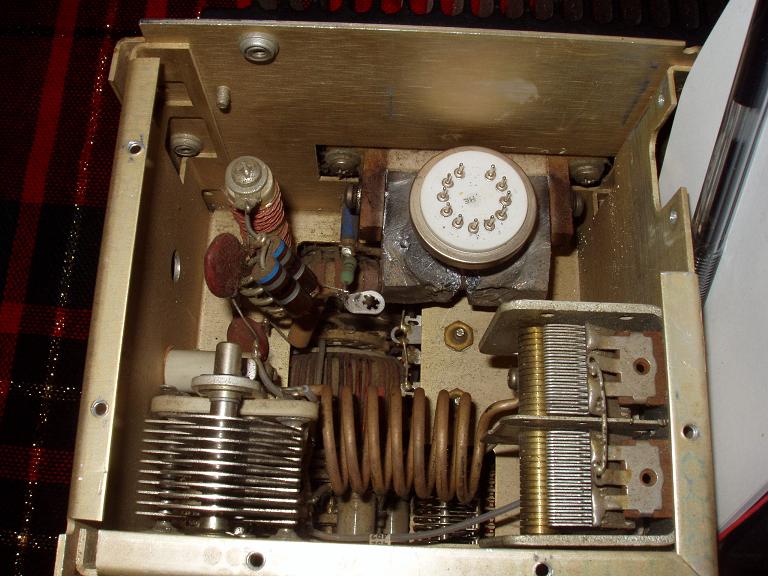

available. Jan, K1ND, discovered a major problem with his CX7B. The

tube clamp had literally melted. I have never seen this happen. It

was a major issue but Jan decided to do the extraordinary and recreate the tube

clamp. Enlisting the help of a friend the task was completed and another

CX7 has returned to the air. This page is devoted to the restoration

process. The information and pictures are from emails that Jan sent during

this project. Jan's radio was in the Registry but it had been a while

since our last contact. This is the first email I received in Dec. 2007

When I did a search for Signal/One CX-7 I came across your web-site

and checked the registry = yup, mine is listed there... also checked the link to

the

archives; I'd forgotten about that too ~ there must be a note to it somewhere in

the

memory above my shoulders.

Well, my CX-7B has been sitting around

for a couple of years now, since it blew a fuse

Now that it's Winter here in Michigan once again I'm starting to think about it

and so took off the case

to see what's the matter with the good old thing.

WOW, it looks like it has had an internal failure ~ wonder why I didn't "smell"

the melt-down?

Well, as you can see, the tube-clamp

has overheated and ----- so far I have not "freed" the 8072 tube

Don't know if I want to

(a) repair this with a custom clamp, OR

(b) might you have a spare, from a parts radio? OR

(c) shall I offer the unit 'as-is' for sale??

We

exchanged a few emails discussing the options and Jan decided to repair the

radio. He has a friend, Gil, K8EAG,

who is a machinist and he agreed to create a tube clamp. June 2008 I

received this email from Jan.

Good evening Fred K5OG

I am all SMILES for the my Signal-One CX-7(b) is back on the AIR

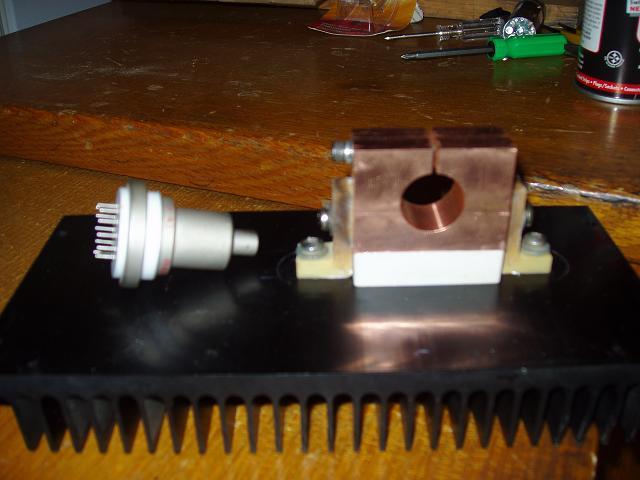

Gil, K8EAG machined me a new tube-clamp out of copper ~ it fits like a glove.

BUT I had to do some more trouble

shooting ~ for when I plugged it in the I found NO BIAS voltage

--I think you made comment about that in an earlier exchange ~ that the failure

and subsequent arcing

might be due to having lost the cut-off bias on the tube. {the RF-choke and the

1-Ohm series resistor

in the high-voltage line show no over-heating}

My concern of course was with the Voltage Doubler circuit for the - 60

volts Bias ((see attached pdf ))

the diodes CR-9 & CR-10 checked-out ok, but not sure about C1 (70uF@50v)

and/or C2 (100uF@150v).

NOW I think the real culprit was R9 (100k@1/4w) ---it tested OPEN---

QUESTION: could this be why (the resistor being open) it

had "no-bias-voltage" ?????

Anyhow, as mentioned at the start of the message the transceiver is back on the

air ~ I did a test with KF2LU

in New York state an hour ago and after 25 minute contact with S9 report; the

heatsink gets quite HOT .. will

have to find the 'muffin-fan' that I used to set behind the rig blow some air

over the heatsink.

I'm going to sleep well tonight ~ cheers,

Jan K1ND

And well deserved. This it the

kind of story I like to put on my web site. Can you believe the quality

and precision in that tube clamp?

The most likely cause of the failure was loss of negative bias to the tube.

There was no damage to the plate choke so that would indicate there was no

excessive plate current. The answer to the above question about the open

resistor is - yes, that is most likely the cause of this failure.

GREAT WORK JAN AND GIL!

Return to

Signal/One Page

Return to

Signal/One Page

Created: June 07, 2008. Last

Updated:

December 04, 2016

Copyright 2017, PakRatz, Corpus Christi, Texas, USA